Opira is the Australian distributor for Guard Tech, and we offer turnkey solutions for clients looking to create, improve, upgrade or relocate a critical environment. Providing expert advice based on a varied portfolio of cleanroom projects, Guardtech excels in working with your specifications and limitations to produce cleanrooms that exceed your expectations – not your budget.

With in-house Designers, full-time specialist Installation Engineers and dedicated Project Managers, Opira is the perfect partner to deliver your cleanroom project on time and within budget. With unrivalled industry knowledge, specially trained staff and a fully validated supply chain, we are tried and trusted by the best in the business.

With the full support of GuardTech, Opira can design and install bespoke environments and laboratories for industries including Pharmaceutical, Electronics, Semiconductor, Aerospace, Automotive, Healthcare, Medical Devices, Optical, Food and Universities.

THE CleanCube Mini is the perfect solution for organisations that need a bit of laboratory or manufacturing space but are restricted by the footprint of their existing premises.

Our CleanCube Mini models are being set up in external spaces such as car parks and unused land and within factory and warehouse facilities all over the UK, allowing businesses to continue their operations despite space limitations.

Mini base models feature three rooms as standard – one process room, a Personnel Airlock and a plant room, with a choice of three internal ceiling heights.

Speak to a member of CleanCube about the different options you have to deck out your unit internally and externally to meet the complex needs of your application.

THE CleanCube Midi offers users all the benefits of the Mini, but with twice the footprint.

This means you get the benefits of an additional process room – improving operator comfort and allowing more sophisticated and complex operations to take place.

Below is a representation of what a user can expect from a standard CleanCube Midi – however, the Guardtech team are on hand to help you tailor your CleanCube to meet the specific needs of your organisation.

Midi base models feature four rooms as standard – two process rooms, a Personnel Airlock and a plant room, with a choice of three internal ceiling heights.

Speak to a member of the CleanCube about the different options you have to deck out your unit internally and externally to fully meet the complex needs of your application.

IF ONE 40ft Midi container doesn’t quite give you the footprint your application requires, then the Maxi is sure to deliver.

Featuring two 40ft containers securely conjoined, the Maxi boasts two impressively large 16m² process areas – giving you more flexibility than ever before to take your operation to the next level whilst still enjoying the benefits of a portable cleanroom.

Below is a representation of what a user can expect from a standard CleanCube Maxi – however, the Guardtech team are on hand to help you tailor your CleanCube to meet the specific needs of your organisation.

Maxi base models feature four rooms as standard – one process room, a Personnel Airlock and a plant room, with a choice of three internal ceiling heights.

Speak to a member of the CleanCube about the different options you have to deck out your unit internally and externally to fully meet the complex needs of your application.

TAKE your portable controlled environment to a whole new level (literally!) with the Guardtech Group’s larger-scale solution – CleanCube Multi.

Containers can be safely and securely conjoined side by side or stacked and connected by staircases, giving the CleanCube Multi all of the usual benefits of a mobile cleanroom but with the flexibility to expand your operation to any size required.

The Multi is available from 3 to 8 containers connected side by side, delivering multiple process areas, a separate PAL and MAL and a plant room.

As your business grows, your needs change – with CleanCube Multi, you can build as high or as wide as you require, giving you peace of mind that with Guardtech, there are limits to where you can go. Unlock your potential with CleanCube Multi.

*Image is for illustration purposes. Actual design will be dependant on room layout selected during the design process.

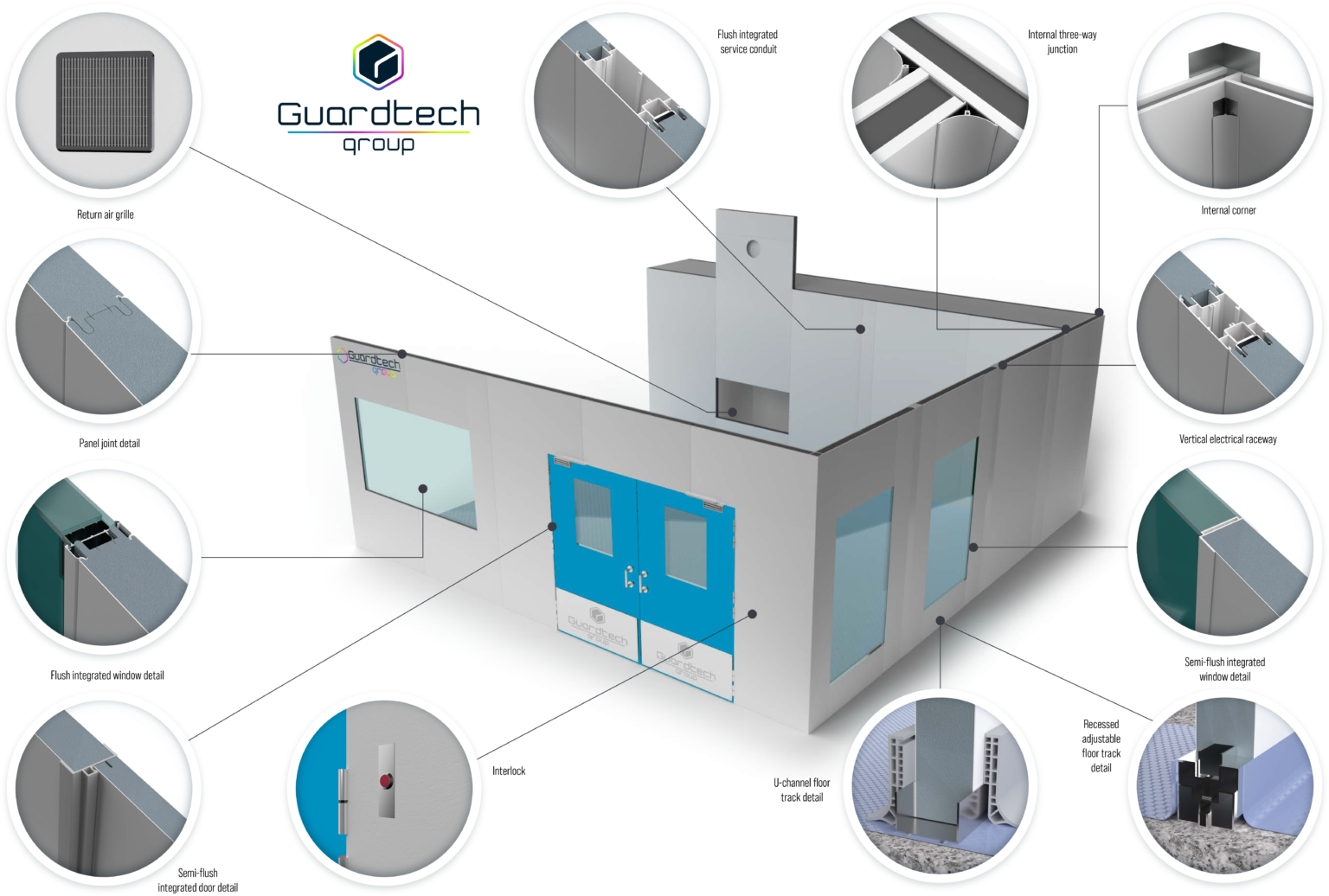

The ISO Specification is the most appropriate combination of components to achieve an ISO 14644 classified environment.

Balancing a high-quality, clean finish with a cost competitive Specification enables CleanCube ISO to meet the full spectrum of ISO 5 to 8 classification whilst ensuring value for money and time to build remain the critical factors.

ISO utilises a composite panel system for the main structural elements, such as walls and ceilings, and ensures that interfacing components including doors, glazing, flooring, lighting, filtration, grilles and accessories are manufactured from high quality materials and intelligently incorporated into the installation.

The CleanCube ISO Specification also logically incorporates and conceals all utilities by taking advantage of the channel behind the wall panels – which also serves as a return air void. This feature reduces ledges and crevices to aid cleaning, support compliance and improve overall facility aesthetic.

32 Dividend Street Mansfield QLD 4122

Phone: 07 3152 1052