C-Cube

What is Clean Cube

A turnkey modular facility for your project. C-CUBE brings a fast, cost effective, transportable and green modular solution for life sciences facilities (bioprocess pilot scale units, BSL2 laboratories, Vaccine production units etc. C-CUBE integrates all the steps from production process engineering, modular solution design through to construction and certification of your final facility. This approach ensures that the project will meet your requirements, schedule and budget.

Benefits of a C-CUBE turnkey modular concept

Nowadays, the Life Sciences industry faces many challenges when building, expanding or even relocating their facilities. In a race to be the first to provide the best treatment for a patient at a competitive price and close to the affected population, implementing a modular project is the best option.

Benefits

Save 50% in time during construction phase compared to other methods.

Firstly, this time savings benefit is due to the minimal design time requirement as a result of pre-engineered solutions; and Secondly, construction efficiency due to the industrial manufacture approach of the modules (lean process, parallel manufacturing).

Your modular facility has an extended life cycle.

It can be modified to suit different applications even after commissioning, thanks to its flexible concept.

It can also be fully relocated.

Modular construction cuts net waste and energy costs, but also improves safety by 95% as manufacture is completed off-site in a lean environment.

Our modules are mobile and sized to allow easy transportation anywhere.

Every module is a stand-alone solution. Modules can be deployed in remote locations and monitored at distance.

Fast build-time and a straightforward qualification process will shorten time to market and increase Net Present Value of your project. Last minute and risk-free decision-making, start small-extend quickly, are now possible business strategies in life sciences thanks to C-CUBE concept.

Based on three size modules of identical width and height, the external layout of your modular cGMP facility is flexible and can be adapted to your needs. Each module side can be completely opened, and modules can also be piled up. Inside layout is also completely adjustable based on your requirements.

Even after final assembly, the facility can still be remodified both internally or externally (e.g. increase footprint, change internal partitions etc.), with minimum disruption to your ongoing operations.

Global construction costs such as engineering design, manufacture and commissioning is 10% cheaper than a conventional construction approach – all the while enjoying an enhanced level of quality.

Your cGMP modular facility is Smart. HMI, EMS and servers are embedded in our modules to provide real-time reporting of your key parameters.

You can access your data remotely and monitor your facility anywhere, anytime, and make adjustments as necessary.

life sciences

The C-CUBE concept allows our customers to build solutions that match their needs regarding surfaces, layout and room classification. Our engineering team studies several scenarios, referencing our three standard modules. Here, we share with you a few examples of our turnkey solutions for life sciences:

Applications

Bioprocess Pilot-Scale Unit

This layout is 167m² and enable us to build a Grade C cleanroom to run a bioprocess pilot-scale or clinical testing.

Legend

- Technical Room: 22.6 m2

- Electrical Room: 10, 4 m2

- Cloakroom: 3.4 m2

- PAL: 8 m2

- IPC: 10.4 m2

- MAL: 6.8 m2

- Clean Corridor: 17.1 m2

- (cell culture)

- Inoculum: 11.2 m2

- DSP: 25.8 m2

- USP: 24.9 m2

- bulk (formulation)

- Final Bulk: 10.4 m2

- Zone CNC: 16.1 m2

Bioprocess Production Unit

- Ramping-up production for a known process

- New green-field facility

- Rapid deployment in a new country

- A back-up production area during a factory refit

Vaccine Production Unit

This concept shows a small unit of 167 m2 for the produciton of vaccines.

This kind of layout can help our customers to deploy rapidly and in any part of the world, ready to produce vaccines in the unit.

BSL2 Laboratories

- Technical Room: 21.7 m2

- Electrical Room: 11.3 m2

- Cleaning Room: 15 m2

- Bacteriology: 15.8 m2

- Cell Culture: 15.7 m2

- PCR: 16.6 m2

- Freezer / Fridge Room: 10.3 m2

- Chemistry Lab: 10.9 m2

- Purification: 10.8 m2

- Office: 11.4 m2

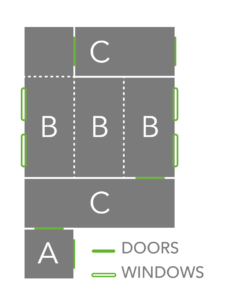

choose your modules

Assemble your modules to define your space

Select your additions

Select Windows, doors, partition locations to finalise your layout.

Specify characteristics

Specify your particular needs and essential characteristic for each space (grade, specifications, utilities.

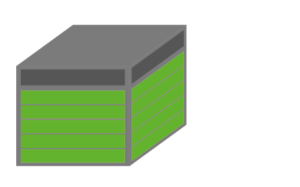

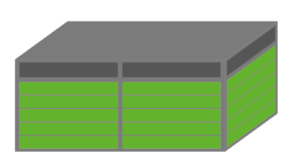

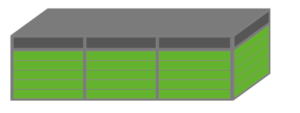

Our concept is based on three pre-engineered modules of 12, 24, 36 m2. They each have all the same height and width but different lengths.

Your facility is made by the assembly of these three smart pre-fabricated modules.

The modules are designed to allow for the maximum of possibilities:

- Full opening of any one side without needing metal reinforcements when building a continuous cleanroom space.

- Stacking of up to 3 modules to accommodate height and equipment of large size.